MK | Cradle Polishing Machine

Description

Purpose:

The device’s primary purpose is to Polish carrots and other root vegetables.

Machine profile and working principle:

The raw material is transferred to the batch of the machine, and then it goes to the polishing drum where it is being rubbed by rotating polishing brushes. For the purpose of achieving a better Polishing effect, the drum is additionally transversely moving in a reciprocating motion (rocking), which also has a beneficial impact on diminished single point wear pertaining too the brushes. The raw material, throughout the polishing procedure, is being rinsed with running water from the sprinklers. The revolution speed for the brushes is adjusted with a frequency transducer, while rocking speed is controlled via the means of a variator. The efficiency of the device is set by the speed of operation of the working elements, quantity of the raw material which is fed, and the opening of the output diaphragm.

Machine Features:

Each of the brush shafts is driven by a single gear motor (for the ECO variant - by V-belts), which assures that operation is steady, smooth and silent. Functional covers provide easy and direct access to the bearings of the brush-shafts. Adjustment of the operation speed of the brushes (inverter) and drum rocking (variator).

Variant of the machine:

- ECO Variant

- Normal steel body (2 industrial lacquer coating layers) + zinc-plated housings, and inox contact elements

- V-belt drive for the brushes

- STANDARD Variant

- Normal steel body (2 industrial lacquer coating layers) + zinc-plated housings, and inox contact elements

- individual gear-motor drives for the brushes

- PRO Variant

- Whole machine created with the use of acid-proof steel.

- individual gear-motor drives for the brushes

All variants are created in left- or right-sided varieties (referring to the location of the controls)

Optional equipment

Water recycling with a circulatory pump.

Specification

| Typ | MK-919 (R) | MK-E919 (R) | |

| Drive method | Direct (Gear motors) |

Indirect (V-belts) |

|

| maximum efficiency | [t/h] | 2,0-4,0 | 2,0-4,0 |

| Number of brushes | [szt] | 9 | 9 |

| Brush length | [mm] | 1900 | 1900 |

| Minimum feeding height (R) | [mm] | 1140 (1780) | 1140 (1780) |

| Minimum output height (R) | [mm] | 605 (1245) | 605 (1245) |

| Total length | [mm] | 2850 | 2850 |

| Total width | [mm] | 1700 | 1700 |

| Minimum total height | [mm] | 2060 (2700) | 2060 (2700) |

| Installed power (R) | [kW] | 5,32 (6,0) | 4,37 (5,0) |

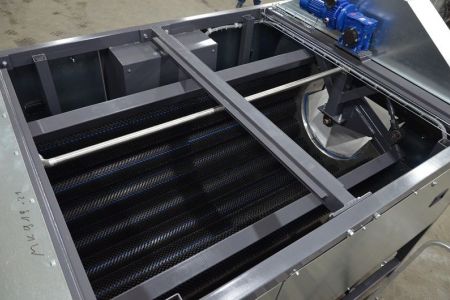

Gallery

MK-919